Command Palette

Search for a command to run...

Ding Han, Academician of the Chinese Academy of Sciences: Humanoid Robots - The Breakthrough Point of the Combination of Robots and Artificial Intelligence

Industrial manufacturing is an important pillar of the national economy and a national weapon for achieving development and upgrading. As early as 2002, the 16th CPC National Congress proposed to promote industrialization through informatization and informatization through industrialization, and to embark on a new path of industrialization with high technological content, good economic benefits, low resource consumption, less environmental pollution, and full utilization of human resources advantages. Since then, "new industrialization" has become a high-frequency word in government documents.

In 2015, "Made in China 2025" was released, which clearly proposed to promote the deep integration of informatization and industrialization, focusing on the development of high-end CNC machine tools, industrial robots, additive manufacturing equipment, and intelligent production lines.

In the past ten years, China's manufacturing industry has embarked on the transformation from "Made in China" to "Smart Manufacturing in China". Today, smart equipment, smart production lines, smart workshops and smart factories are widely used and promoted in domestic enterprises. From improving quality and efficiency to energy conservation and carbon reduction, information technology, automation technology and artificial intelligence technology are everywhere to empower traditional manufacturing.

As one of the key technologies of intelligent manufacturing, robots integrate emerging technologies such as new materials, smart sensors and artificial intelligence. They can directly participate in the manufacturing process and replace manual work to complete dangerous or repetitive tasks. Robots have become an important force in promoting the digital transformation of China's manufacturing industry.

"Robots are the limbs of intelligent manufacturing, and the ultimate goal of intelligent manufacturing is human-machine integration."Ding Han, an academician of the Chinese Academy of Sciences, recently attended the first annual academic conference of the Shanghai Institute of Artificial Intelligence and Finance at East China Normal University and shared his analysis of the development trend of robots. He proposed that“Robots can enable ubiquitous manufacturing.”

HyperAI was fortunate to have an in-depth interview with Academician Ding Han to further understand his profound accumulation in the field of intelligent manufacturing, as well as his unique insights into research fields such as industrial robots and humanoid robots.

Robots are an important foothold for artificial intelligence technology

The first industrial revolution was marked by the replacement of human and animal power by machines, becoming an important milestone in the development of human society. The second industrial revolution witnessed the large-scale application of electricity, which promoted the establishment of factories and centralized industrial manufacturing. The importance of professional technology also became increasingly prominent with the deepening of the division of labor.

The third industrial revolution, namely the information technology revolution, centered on technological innovations such as computers, digital communications, and the Internet, has accelerated the improvement of production efficiency.It was also during this period that industrial robots were born. In 1959, Americans Ingeborg and Devol created the world's first industrial robot "Unimate" and put it into use on the production line of General Motors' die-casting plant, bringing robots from fantasy into reality.

However, robots in the 1950s mainly completed simple repetitive movements in the form of mechanical arms, and the concept of "human" had not yet been formed. At that time, programmable mechanical arms could only complete basic work of a single type of work according to the program. In the past decade, with the upgrading of underlying technologies and products such as the Internet of Things and visual sensors, as well as the deepening application of artificial intelligence technology, machines have begun to gain decision-making capabilities in industrial manufacturing environments, truly moving towards "robots."

Academician Ding Han proposed that in the future, with the deep integration of electromechanical systems and life systems,The development trend of robots is to have higher environmental adaptability and autonomy.Humanoid robots are expected to make autonomous decisions in unstructured environments, and the seamless integration of artificial intelligence, large models and sensors will bring greater innovation and breakthroughs to robotics technology.

Academician Ding Han emphasized: "In the future, robots will be an important foothold for artificial intelligence."He believes that the application expansion of artificial intelligence should focus on "helping people, expanding people, and serving people", and through technological progress, liberate humans from tedious affairs and enable them to engage in more advanced and creative activities.He believes that the next ten years will be a period of explosive growth for the combination of robots and artificial intelligence.

Returning to the field of industrial manufacturing, he believes that "robots are the limbs of intelligent manufacturing" and will develop from the initial interaction with parts to complex interactions with the environment, people and other robots. Robotic manufacturing will also provide new ideas for the efficient and high-precision processing of core components in strategic areas.

Humanoid robots are the epitome and pinnacle of robotics technology

Although the original robots were not capable of performing delicate manufacturing tasks in factories and their accuracy and sensitivity could not compare with machine tools, with the advancement of technology, robots are changing the landscape of industrial manufacturing.

At present, many companies are promoting "dark factories", that is, completely unmanned smart factories that rely on machines to operate automatically. Industrial robots and robotic arms are widely used, but they are mainly responsible for some large-scale, standardized processing and manufacturing, and perform identification, feedback and cyclic operations according to pre-set programs and algorithms. For some small-batch, highly skilled precision parts processing, traditional robots are not competent.

In response to this challenge, Academician Ding Han believes that humanoid robots and dexterous manipulation have great potential and value in the industrial world.Humanoid robots involve the intersection and integration of multiple disciplines such as mechanics, electrical appliances, materials, sensing, control, and artificial intelligence, and are internationally recognized as the integrator and commanding heights of robotics technology.

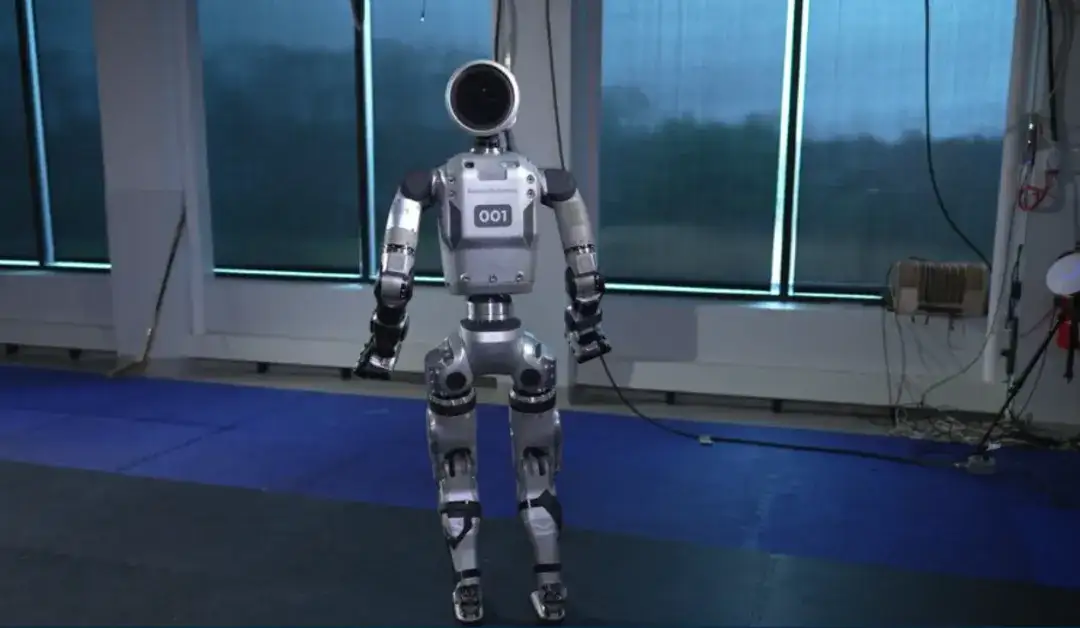

In recent years, many companies at home and abroad have invested in the humanoid robot track. Atlas, built by Boston Dynamics with a hydraulic system, has continuously refreshed people's understanding of robots from toddling to walking with a breeze. Although the hydraulic Atlas has been "retired", it has laid the foundation for the development of humanoid robots.

Tesla founder Musk announced his entry into the field of humanoid robots in 2021, and released a video of the second-generation Optimus walking inside the Tesla factory in early 2024. Nvidia founder Huang Renxun also proposed that humanoid robots will change the industrial world, and introduced a humanoid robot based on the Nvidia GR00 platform at this year's GTC conference.

In China, UBTECH successfully entered the capital market at the end of 2023, becoming the "first stock of humanoid robots". Zhiyuan Robotics, founded by "Huawei genius boy Zhihuijun" after leaving Huawei, also released its first general-purpose embodied intelligent robot "Expedition A1" in August 2023.

In essence, humanoid robots can be divided into two parts: "humanoid" and "robot". "Humanoid" means that its appearance adopts the design of human's two feet and two hands, and completes various tasks in a form closer to the way humans work; "robot" requires it to have certain decision-making ability and be able to think like a human, rather than a machine that executes a set program.

Academician Ding Han believes that having judgment consciousness is one of the disruptive changes of humanoid robots.For example, in the past, household robots (such as sweeping robots) would clean according to a planned route only after the user started the program. However, robots with judgment awareness can detect garbage or clutter in the house or on the desktop based on machine vision and smart sensors, and actively organize and clean them.

On the technical level, Academician Ding Han proposed that we should accelerate the application of humanoid robots in special environments to meet the needs of operations in harsh conditions and dangerous scenes.Strengthen its ability to control itself, move quickly, and perceive accurately in complex environments.Create highly reliable humanoid robot solutions for special application scenarios.

Academician Ding Han is determined to tackle the problem of robotics technology

It is undeniable that during the three industrial revolutions, my country has a certain gap with Western countries in terms of technological autonomy and innovation. However, in recent years, with the development of technologies such as 5G, Internet of Things, and AI, domestic scientific research and industry have seized the opportunity to catch up or even run parallel in some fields.

Academician Ding Han believes thatOne of our country’s major advantages is its rich scenarios, which can drive technological breakthroughs.He pointed out that my country is currently in a period of industrial transformation, and many application scenarios have emerged. If we can focus on scenarios and manufacturing tasks, it will be able to enhance my country's technological level in related fields and make substantial contributions to industry progress.

As one of the earliest scholars to enter the field of robotics research, Academician Ding Han has witnessed the journey of industrial robots overcoming difficulties and making breakthroughs.

As early as 1986, Ding Han began to conduct research in the field of robotics with his mentor. Since 2001, he and his team have developed more than 20 sets of industrial robot operation systems, which are widely used in welding, assembly, palletizing and machining.The research result "Research, development and application of key technologies of industrial robot operation system" won the second prize of National Science and Technology Progress Award. In 2005, he began to engage in basic research on digital manufacturing, and presided over the first National Key Basic Research and Development Program (973 Program) project in the field of digital manufacturing and received rolling support.

Around 2012, Ding Han keenly perceived the broad prospects of robotized manufacturing and began to integrate robots with digital manufacturing technologies, creating a new direction for robotized intelligent manufacturing and promoting the transformation of the manufacturing model from "iron machine tools, changing workpieces" to "iron workpieces, changing machine tools".

In 2016, he served as the leader of the guidance expert group for the National Natural Science Foundation's major research project "Research on Basic Theories and Key Technologies of Inclusive Robots", and took the lead in the world in conducting research on basic theories and key technologies of inclusive robots.

In 2017, he presided over the national key R&D project "Robot intelligent grinding and polishing technology and system for large wind turbine blades", and his research results "Multi-robot intelligent grinding and polishing technology for large components" were selected as one of the top ten scientific and technological advances in China's intelligent manufacturing in 2018.

In addition to actively promoting independent control of core technologies, Ding Han also emphasized that"We need to look at things in two ways: on the one hand, we need to be autonomous and controllable, and on the other hand, we need to engage in global cooperation in technology."

Conclusion: When smart machine tools and humanoid robots become the norm in factories

Academician Ding Han believes that in the future, the application space and scope of robots will continue to expand. In the complex industrial manufacturing industry with different subdivided fields, artificial intelligence algorithms will further promote the possibility of real-time online detection and measurement, especially when my country's AI chips and sensors continue to make breakthroughs."Machine tools will become smart machine tools".

At the same time, he predicted,Humanoid robots will enter factories.Replace humans in completing repetitive, boring, and health-damaging tasks, allowing humans to focus on more valuable and meaningful work.