Command Palette

Search for a command to run...

Reac-Discovery Integrates Mathematical Modeling, Machine Learning, and Automated Experiments to Address the Versatility Challenges of self-driving Laboratory systems.

In the past, 3D printing technology was used to precisely create "periodic open pore structures (POCs)" with regular pores in reactor engineering. These structures, known as "grid-like" reactors, allowed for the smooth flow of gases, liquids, and heat, potentially improving reaction efficiency. The addition of artificial intelligence (AI) has further enhanced the laboratory's ability to self-regulate: automated platforms can monitor temperature, flow rate, and reaction progress in real time and autonomously optimize experimental plans based on this data.These systems, called Self-Driving Laboratories (SDLs), are bringing unprecedented precision and speed to reactor design.

However, despite the breakthroughs brought about by the combination of digitalization and automated experiments, existing research still lacks a unified model for geometric parameters such as porosity, surface area, and tortuosity. Traditional methods such as computational fluid dynamics (CFD) simulation not only have limitations such as low efficiency and high computational cost, but the design of structured reactors often relies on manual experience and dedicated software.The lack of a universally applicable framework results in limited reusability and universality among different systems.

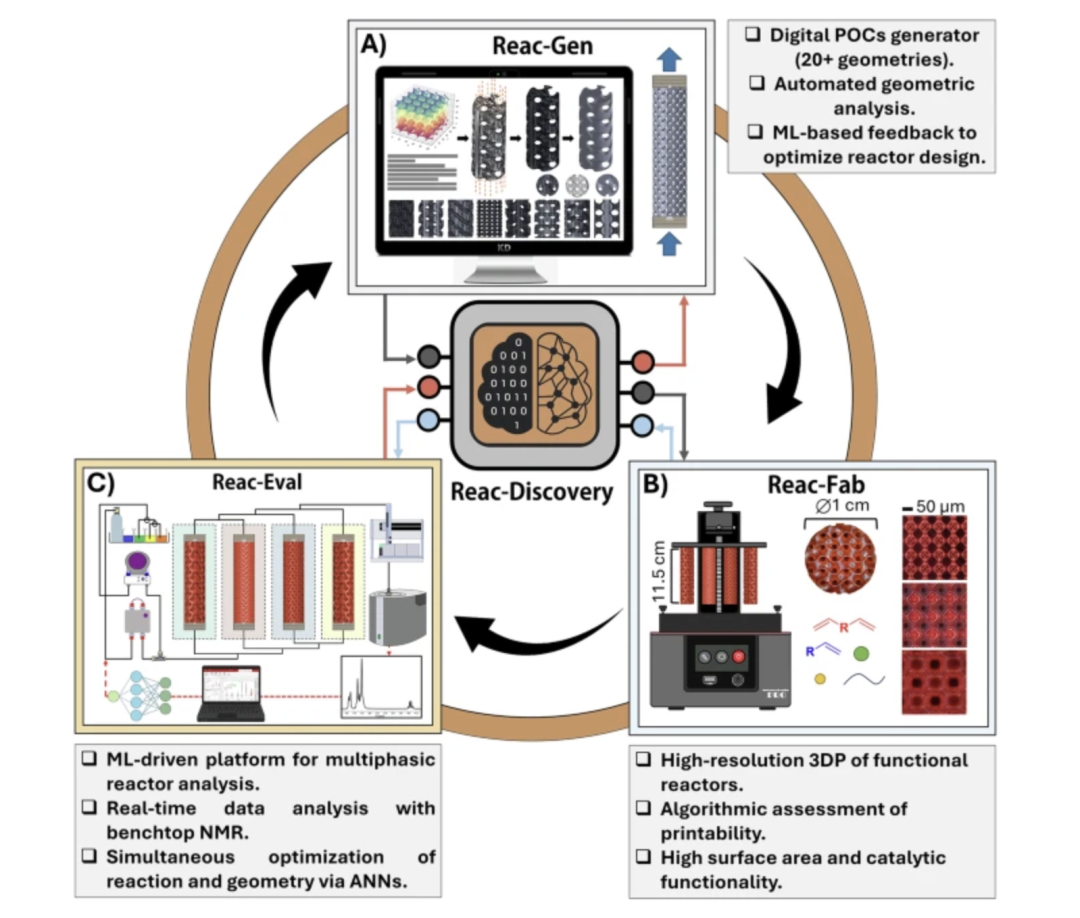

In response to the limitations of traditional methods, a research team from the Spanish IMDEA Materials Research Institute launched the Reac-Discovery semi-autonomous digital platform.Based on a periodic open-pore structure, a closed-loop system with integrated design, manufacturing, and optimization modules is adopted, which can perform multi-reactor evaluation in parallel and has the functions of real-time nuclear magnetic resonance (NMR) monitoring, machine learning (ML) optimization of process parameters and topological descriptors.While improving performance, reaction efficiency and reducing material consumption, the versatility of the system is increased.

The relevant research results were published in Nature Communications under the title "Reac-Discovery: an artificial intelligence–driven platform for continuous-flow catalytic reactor discovery and optimization."

Research highlights:

* Integrate mathematical modeling, machine learning, and automated experimental systems to integrate the entire catalytic reactor process from geometric design and 3D printing to experimental optimization;

* Incorporating topological parameters into the optimization space breaks through the limitations of traditional methods of controlling single variables such as temperature and flow rate, and achieves simultaneous optimization of geometric structure and process conditions;

* Build a neural network-based performance prediction model, develop a machine learning-driven algorithm system, and use the performance model to achieve rapid evaluation and iteration of reactor performance, significantly improving experimental efficiency and resource utilization.

Paper address:

Follow the official account and reply "Periodic Drilling" to get the full PDF

More AI frontier papers:

Autonomously generate data sets to support closed-loop optimization

This study did not utilize publicly available datasets. Relying on the Reac-Discovery platform, the research team independently generated a multidimensional internal data set covering geometry, printability, and reaction performance during the experiment. Based on the platform's three functional modules, Reac-Gen, Reac-Fab, and Reac-Eval, the dataset generated by this study is divided into three parts:

* Structural parameterized datasets: Reac-Gen uses mathematical parameterized models to generate periodic open cell structures (POCs). The output is controlled by parameters such as size, threshold, and resolution, providing quantitative input for topology optimization.

* Printability dataset: generated by Reac-Fab after establishing the correspondence between structural parameters and printing results;

* Reaction performance dataset: Reac-Eval is generated by real-time recording of temperature, flow rate, concentration, and yield data during parallel experiments in the Self-Driving Laboratory (SDL).

Currently, the data generated by the closed-loop framework, from structure generation to performance verification, has been uploaded to Zenodo.

Dataset link:

https://hyper.ai/datasets/45520

Reac-Discovery: Three-module integration to achieve an integrated process closed loop

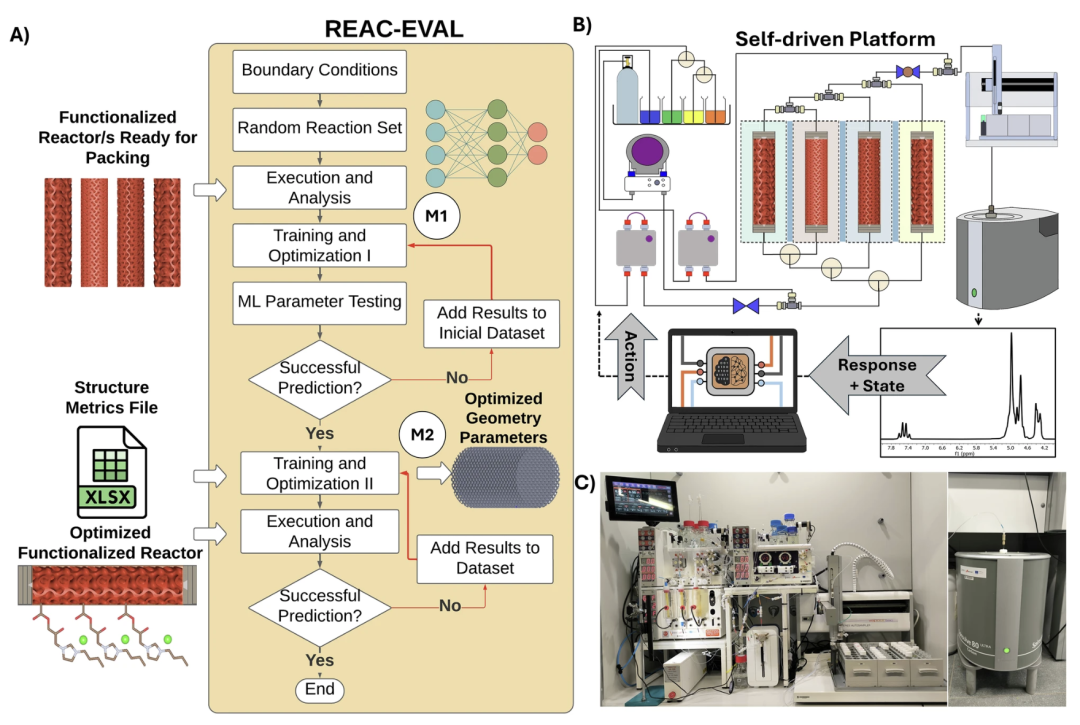

Reac-Discovery's overall architecture is centered around machine learning (ML), forming an integrated process closed loop of "generation-manufacturing-evaluation-optimization" based on data feedback.The closed-loop platform is mainly divided into three modules: Reac-Gen, Reac-Fab, and Reac-Discovery. The functions of each module are interconnected during operation:

* Reac-Gen: Parametric generation and geometric analysis of periodic open cell (POC) structures, with feedback provided through machine learning (ML);

* Reac-Fab: Validation of the printability and fabrication of a reactor using a high-resolution 3D printing algorithm, followed by catalytic functionalization;

* Reac-Eval: Leveraging machine learning and real-time nuclear magnetic resonance (NMR) monitoring data analysis, an artificial neural network (ANN) is used to simultaneously optimize process and geometry. Experimental results are then fed back into the core machine learning model to drive the reactor's self-learning and self-iterative cycle.

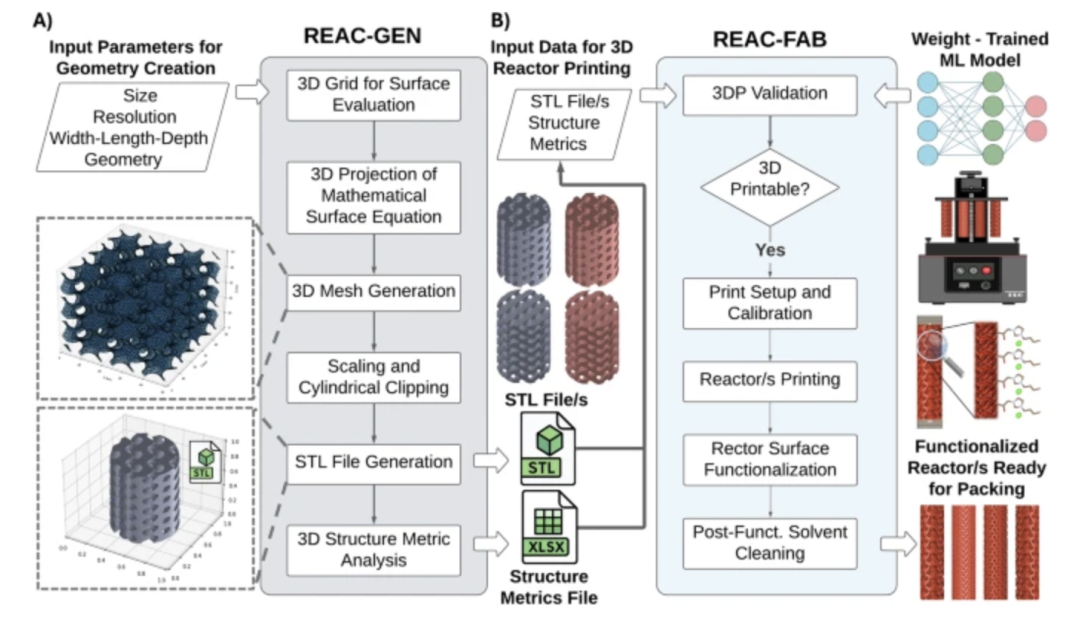

Reac-Gen: Geometric Modeling and Parametric Design

The Reac-Gen module is the starting point module of the Reac-Discovery system, responsible for the reactor geometry design and parametric modeling.This module generates periodic open-pore structures based on a set of predefined mathematical equations, including Gyroid, Schwarz, Schoen-G, etc., and generates diverse geometric topologies at the "macro + micro" scale by adjusting the three main parameters: size (S), horizontal threshold (L) and resolution (R).Among the three modules, Reac-Gen is mainly responsible for digital modeling and structural quantification. Its workflow is divided into the following main steps:

First, the key geometric parameters of the structure are input. The system builds a model in a three-dimensional scalar field based on predefined mathematical equations and generates implicit surfaces through isosurface calculations to determine the overall shape and internal topology of the reactor.

* Projecting the equations into three-dimensional space and algorithmically performing meshing, scaling, and cylindrical cropping to adapt the structure to the reactor shape, resulting in a high-fidelity three-dimensional structure. Simultaneously, boundary smoothness and pore continuity are automatically corrected to ensure the structure has reasonable physical connectivity and stability during both printing and fluid simulations.

Generates manufacturing and data analysis files for input into the next module, Reac-Fab, providing core input for subsequent printability prediction, 3D manufacturing, and performance data analysis.

In the data output step, the data files output by Reac-Gen are divided into two categories:

* STL file: for 3D printing;

* Structural feature file (XLSX): records geometric descriptors such as surface area, porosity, tortuosity, hydraulic diameter, etc.

Reac-Fab: From feasibility verification to sample printing

The Reac-Fab module is mainly responsible for the physical manufacturing of the reactor.High-resolution stereolithography (SLA) 3D printing technology is used to achieve structure construction. The workflow of this module is divided into two steps:

* Receive STL and structure data output by Reac-Gen, use machine learning models to predict structure printability, and perform print settings and equipment calibration;

* The structure is printed using high-resolution SLA technology. Using optimized material formulations and parameters, the printed samples are subjected to functionalization treatments such as surface chemical modification and immobilization of catalytically active components to obtain the samples.

The module employs an algorithm based on a neural network classification model for printability verification. The algorithm uses 236 experimental samples as training data. The model compares the theoretical weights of key geometric descriptors with the experimental weights to determine whether the structure is printable.Experimental data demonstrates that this method achieves a prediction accuracy of 91%, effectively improving manufacturing efficiency and reducing experimental costs. Furthermore, the module can be run without extensive pre-experimentation, enhancing the algorithm's applicability and scalability across various printing systems, such as FDM printing using PLA.

Reac-Eval: Experimental Verification and Dual Optimization

Reac-Eval is the core module for experimental verification and optimization in the Reac-Discovery platform. This module integrates the ability to simultaneously evaluate multiple structured catalytic reactors designed by Reac-Gen and printed by Reac-Fab.It can monitor and automatically control multiphase reactions in real time.All hardware is integrated through a unified Python-based interface to ensure seamless integration between experimental data, predictive models, and control systems. The Reac-Eval workflow consists of five steps:

* Define boundary conditions such as gas-liquid flow rate, temperature, concentration, and topological descriptor range, generate randomized experimental combination coverage parameters, and complete experimental initialization and condition setting;

* Operate multiple structured reactors in parallel on a self-propelled platform, monitor reaction progress in real time using benchtop NMR, and collect performance data;

* Based on machine learning and neural network model M1, process variables and process parameters are optimized, and repeated training based on the initial data set does not achieve the expected optimization results;

* Optimize the geometric parameters of the reactor based on the neural network model M2;

* Generate an optimized reactor design based on the prediction results of M2, conduct a secondary experimental verification, and return the data that does not meet expectations to the model for further training.

In general, while achieving dual optimization of process parameters and geometric topology, the Reac-Eval module builds an automated cycle of experimentation, modeling, and feedback based on a self-driving platform.

Reac-Discovery application effect double verification

To demonstrate the practical effectiveness of Reac-Discovery in multiscale coupling and machine learning-driven optimization, the research team selected two typical heterogeneous catalytic reactions: acetophenone hydrogenation and CO₂ cycloaddition. Involving three-phase gas-liquid-solid transformations, the mild hydrogenation of acetophenone and the highly complex thermodynamics of CO₂ cycloaddition provide the foundation for verifying the robustness, stability, and repeatability of the system in self-optimization and topology reconstruction.

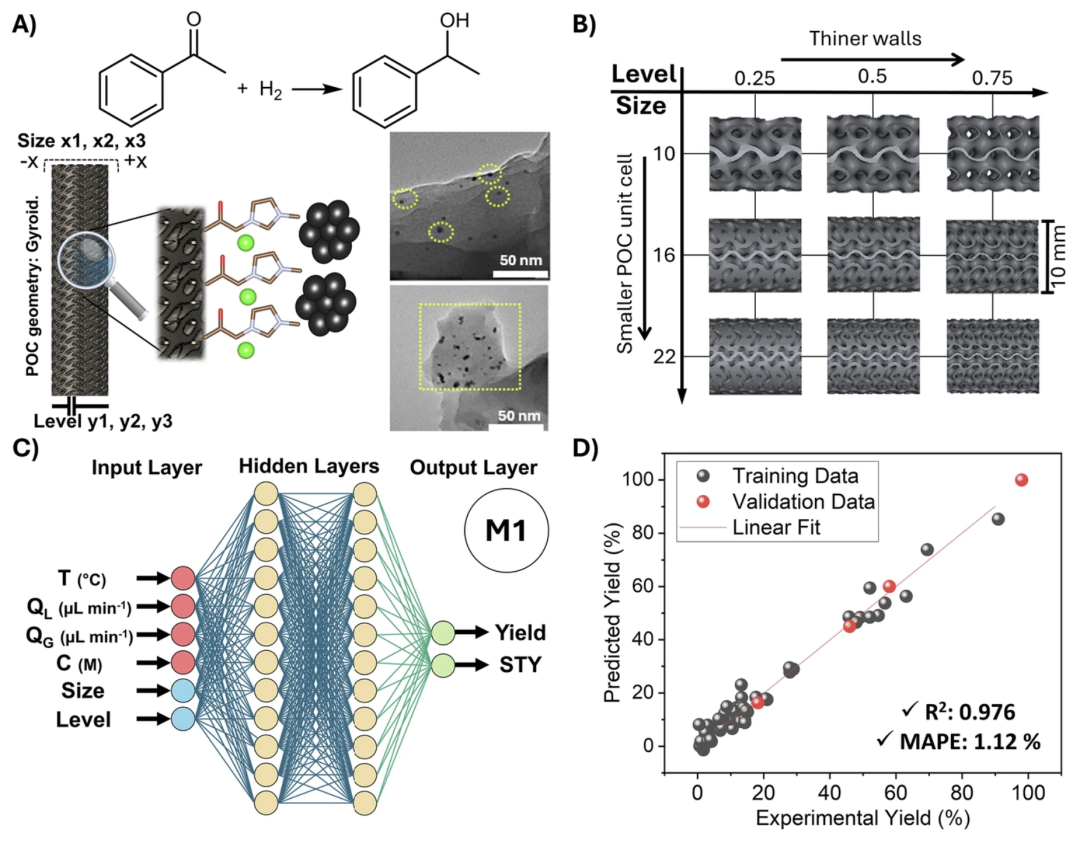

Verification of acetophenone hydrogenation reaction

In the acetophenone hydrogenation reaction verification experiment, the research team selected acetophenone hydrogenation reaction as the test object.Using immobilized palladium nanoparticles (PdNPs) as catalysts, the optimization capability of Reac-Discovery in complex heterogeneous catalytic reactions was evaluated using a two-stage optimization approach:

First optimization phase (G1): Nine gyroid geometries were generated using Reac-Gen to construct reactors with significantly different porosity and surface areas. The Reac-Eval module performed 60 hydrogenation experiments, monitoring the reactions in real time using nuclear magnetic resonance (NMR) and collecting data for training the M1 correlation model.

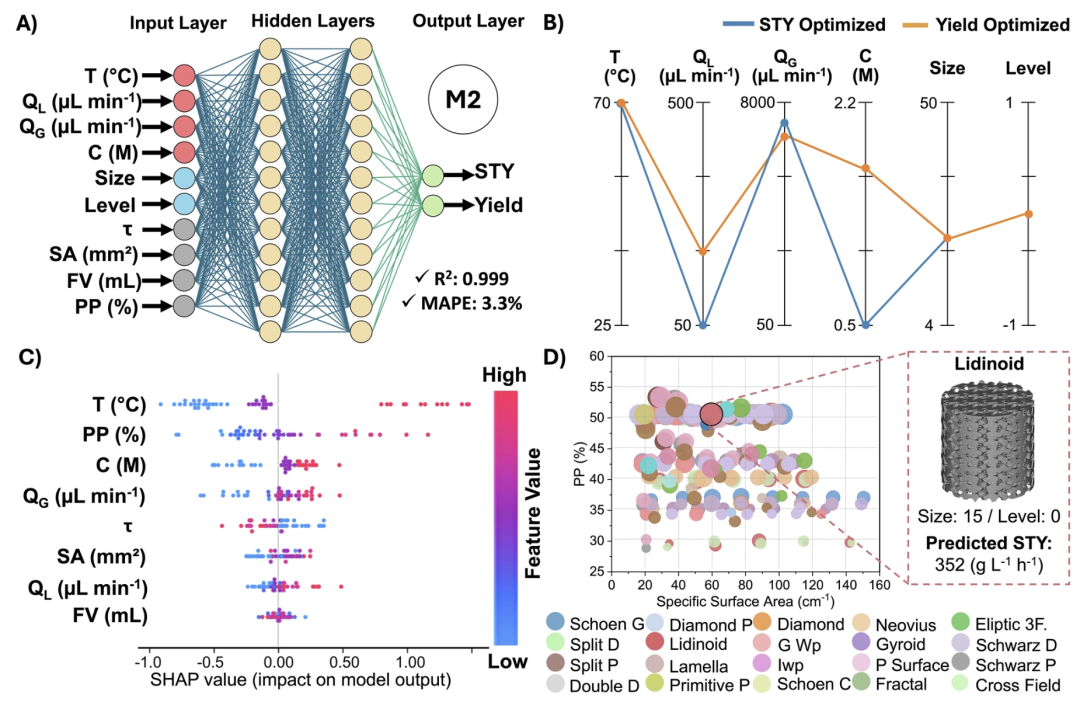

* Second optimization stage (G2): Based on the M2 model, the structural descriptor is incorporated into the learning process to achieve joint optimization of structure and performance.

Experimental data demonstrates high consistency between the M1 model's predictions and experimental results, enabling the identification of optimal process ranges among over one million parameter combinations, significantly reducing experimental exploration costs. Furthermore, in the G2 phase, the M2 model's prediction accuracy was further enhanced, enabling the identification of optimal geometries by screening and comparing 480 printable POC structures. This demonstrates the high accuracy and robustness of the Reac-Discovery platform in multivariable optimization and structure-function prediction.

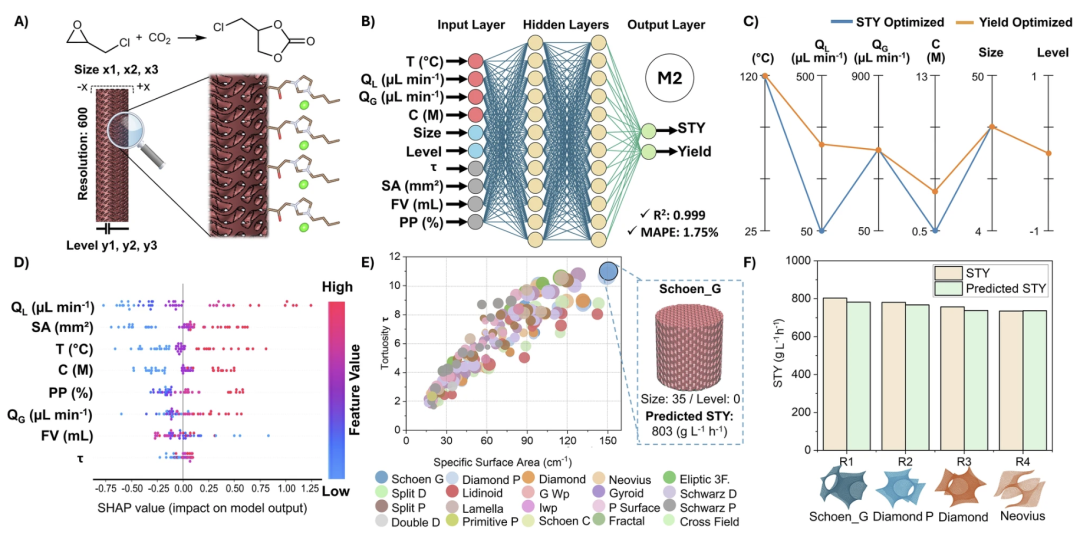

CO₂ cycloaddition reaction

To further verify the platform's adaptability in complex multiphase systems, the research team conducted a verification experiment using a CO₂ cycloaddition reaction:

* Phase 1 (G1): Based on the Reac-Eval module, 60 sets of experimental conditions were completed through a self-driven experimental platform. The initial data set was generated using real-time nuclear magnetic resonance monitoring. The neural network model M1 was used to predict the yield and screen out the theoretically optimal conditions.

* Phase 1 (G2): Integrate geometric descriptors and process parameters based on model M2, optimize reactor topology and reaction conditions, and determine the geometric optimal solution by comparing printable POC structures.

The experimental results show that the theoretical optimal conditions screened out by the experiment are completely consistent with the predicted values, refreshing the performance upper limit of the current three-phase immobilized reactor.The Reac-Discovery reactor consistently maintained high conversion rates of 40% to 90% in four different epoxide systems, verifying the cross-system generalization and stability of Reac-Discovery.

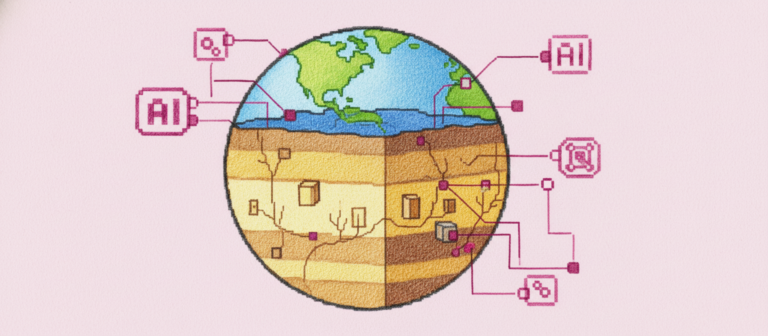

AI integration: Self-driving laboratories become a new paradigm for chemical research

The rapid integration of artificial intelligence in flow chemistry and reactor engineering is making self-driving laboratories a new paradigm in chemical research. In July 2025, a research team from North Carolina State University published a paper titled "Machine learning-assisted discovery of flow reactor designs."To address the problems that traditional chemical experiments rely on manual trial and error, are inefficient and lack repeatability, a new flow chemistry framework based on a self-driving laboratory is proposed.The framework combines an automated experimental platform with real-time data analysis and artificial intelligence decision-making, realizing an integrated closed loop of reaction design, execution and optimization, significantly improving the accuracy, efficiency and scalability of the reaction process.

Paper address:

https://doi.org/10.1038/s44286-024-00099-1

A research team from the Department of Chemistry at the University of Toronto also uses self-driving laboratories as a new paradigm for chemical research.Integrate automated experimental hardware, real-time data analysis, and AI planning and decision-making to achieve a closed loop of experimental design, execution, analysis, and optimization.This research utilizes a high-frequency automated experimental platform to generate high-density data. Incorporating AI algorithms such as Bayesian optimization and reinforcement learning, this allows for autonomous design and iterative advancement of experimental procedures, significantly improving discovery efficiency and scalability. The research findings have been published in ACS Publications under the title "Self-Driving Laboratories for Chemistry and Materials Science."

Paper address:

https://pubs.acs.org/doi/10.1021/acs.chemrev.4c00055

In July 2025, the Royal Society published an article in Open Science stating that the core of self-driving laboratories consists of hardware automation, algorithm optimization, and self-learning feedback. These labs can execute experiments and iteratively improve them without human intervention, achieving a closed loop from experimental design to result verification, accelerating the discovery process in chemistry and materials science. "Self-driving laboratories may even replace some scientific research positions, but they may also create many new opportunities." Currently, self-driving laboratories face challenges such as high system costs, insufficient data standardization, limited model generalization capabilities, and safety and ethical risks. However, as the integration of algorithms and hardware continues to mature, self-driving laboratories may reshape the scientific research system in the future, creating a more efficient, repeatable, and intelligent model of scientific exploration.

Reference Links:

1.https://royalsocietypublishing.org/doi/10.1098/rsos.250646#d717644e1

2.https://www.nature.com/articles/s41467-025-64127-1

3.https://pubs.acs.org/doi/10.1021/acs.chemrev.4c00055

4.https://doi.org/10.1038/s44286-024-00099-1