Command Palette

Search for a command to run...

AI Empowers Efficient Biomanufacturing, Exploring New Paradigms in Intelligent Production Through Research on Β-phenylethanol and Glutathione

Biomanufacturing is a core driving force behind the development of the bioeconomy. By harnessing the metabolic activities of living cells to produce a wide range of products, it plays a crucial role in ensuring sustainable social development. The rise of synthetic biology has provided powerful tools for constructing efficient strains. Bioreactor engineering, a core component of biomanufacturing, combined with intelligent technologies is crucial for its industrialization. In recent years, advances in AI, big data, and advanced sensing technologies have enabled new breakthroughs in the efficient optimization and precise control of biomanufacturing processes.

Recently, at the 3rd AI for Bioengineering Summer School in 2025,Professor Zhuang Yingping from the National Key Laboratory of Bioreactor Engineering at East China University of Science and Technology shared her experience on "AI Assists Efficient Biomanufacturing Processes".From the relationship between biomanufacturing and synthetic biology, the application exploration of synthetic biology products, to the construction and practice of intelligent biomanufacturing technology systems, the team's research results in this field were systematically introduced.

HyperAI has compiled and summarized Professor Zhuang Yingping's in-depth sharing without violating the original intention. The following is the transcript of the speech.

Biomanufacturing and synthetic biology complement each other

The essence of biomanufacturing technology is the process in which various living cell lines use raw materials (such as carbon sources, nitrogen sources, starch, glucose, etc.) in reactors to produce various biological products through cellular metabolism.Synthetic biology achieves design goals, changes production methods and develops new products through the DBTL (Design-Build-Test-Learn) cycle.Technological breakthroughs such as gene editing and host modification have provided efficient chassis cells for biomanufacturing - but converting the potential of laboratory strains into industrial production capacity requires the support of bioreactor engineering.

With the popularity of synthetic biology technology in recent years, research on bioreactor engineering has become an important focus in the industry. The global biomanufacturing industry is expected to reach US$125 billion in 2025, with a compound annual growth rate of 10.81%; the annual output value of China's bio-industry is growing at a rate of nearly 20.1%. Against this background,How to make the same strain produce more products in a reactor? This is the core issue of biomanufacturing.

Exploration of synthetic biology products in the cosmetics field

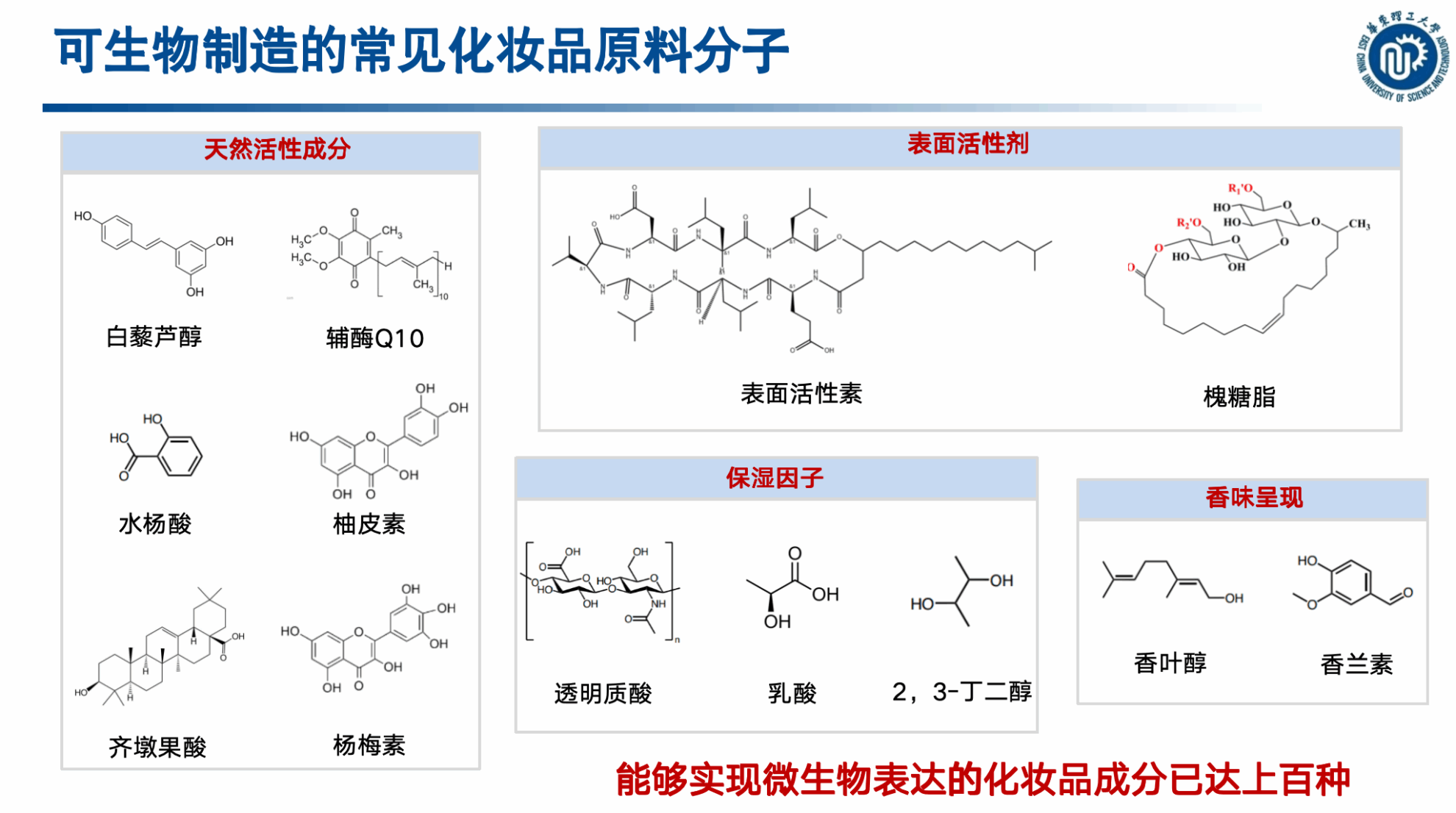

The application of synthetic biology and biomanufacturing in the cosmetics field is relatively mature and has a wide range of applications. This is because cosmetics require small amounts, and even if the cost is high, there is still a market. For example, after large-scale cultivation of Tianshan Snow Lotus, only a small amount can cause the price of related products to rise significantly. In addition, many cosmetic products are derived from natural active ingredients, such as resveratrol, naringenin, coenzyme Q10, etc.Although there are currently hundreds of cosmetics that can be expressed by microorganisms, only a handful of them are truly fully biomanufactured.

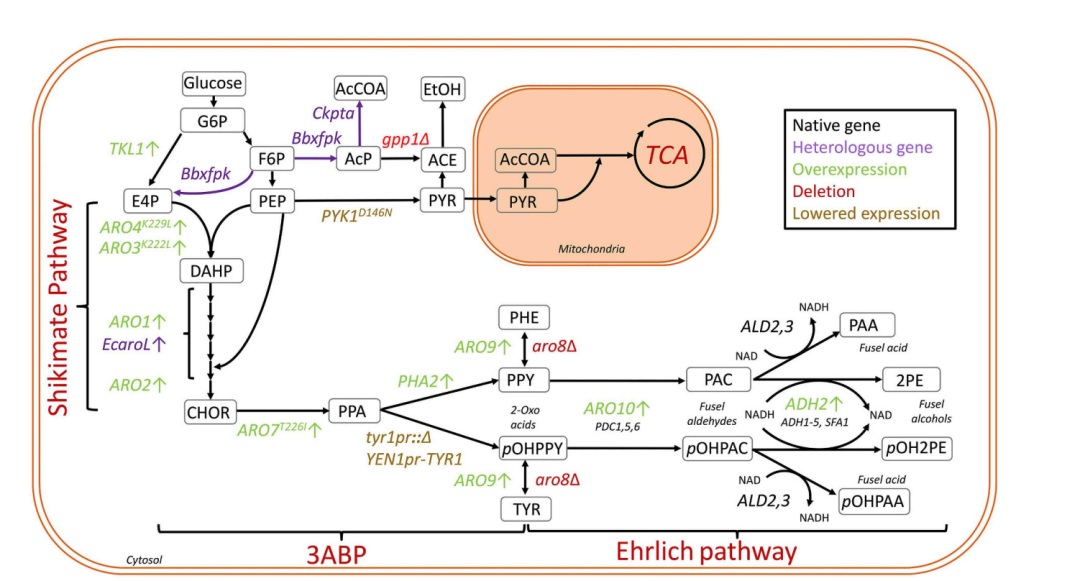

Taking β-phenylethanol studied by our team as an example, from the transformation of the original bacteria to process engineering research, its production has reached a certain level. Although it is close to industrialization, the cost is not yet on par with chemical sources. In addition, the surfactant project we did for a German company achieved good results through high-throughput screening and fermentation tank yield improvement.

* Paper address:Hassing, EJ, de Groot, PA, Marquenie, VR, Pronk, JT, & Daran, JMG (2019). Connecting central carbon and aromatic amino acid metabolisms to improve de novo 2-phenylethanol production in Saccharomyces cerevisiae. Metabolic Engineering, 56, 165-180.

Plant active ingredients have been a hot research area in recent years. Plant cells can produce a variety of products, and their large-scale cultivation has a specific process: first, the callus tissue is sorted, and then it is cultured on a shaker until the cell count increases. Because plant cells have a slightly lower oxygen requirement than microorganisms, airlift culture is used to achieve a certain cell mass.

Synthetic biology technology is used in many cosmetics, among which hyaluronic acid and collagen are the best and largest industries in my country using synthetic biology technology. Such high-value-added products are more suitable for synthetic biology manufacturing.

Bioreactors and Intelligent Biomanufacturing

The key to improving intelligent biomanufacturing technology and thus increasing efficiency lies in establishing the concept that "cells and external reactors are two reactors."Consider cells as a bioreactor system and large-scale culture as another bioreactor system.Cells themselves are complex metabolic systems, and the metabolic pathways we need for synthetic products are specific. The core of process engineering is to guide cells to metabolize along designed metabolic pathways, rather than relying solely on constructed strains for direct production. This requires focusing on how to make cell metabolism focus on the target synthetic pathway.

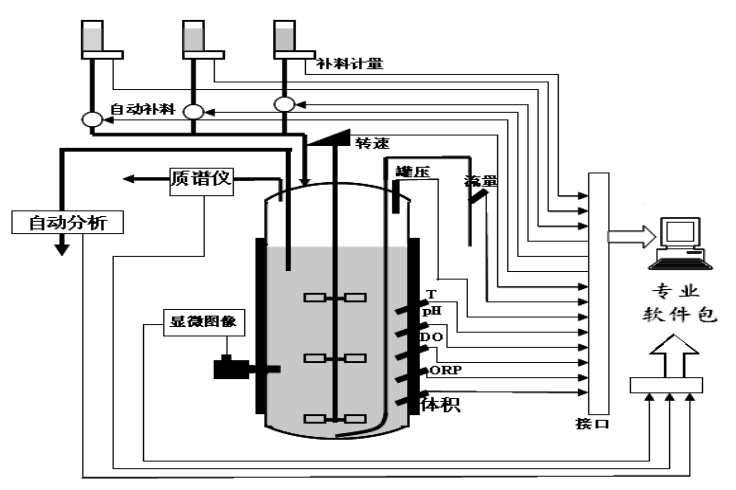

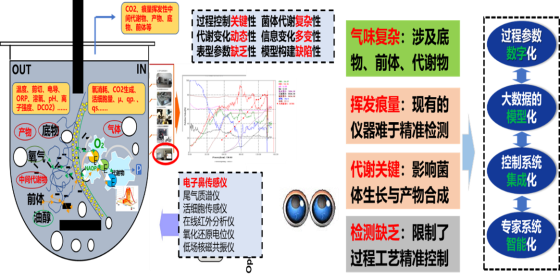

To advance process engineering research, we have specially developed a bioreactor for multi-parameter detection, which is also a feature of the National Key Laboratory of Bioreactor Engineering.In addition to routine detection of bacterial flora and temperature, the technology system also monitors the volume of fermentation liquid, and more importantly, uses a proton meter to detect the tail gas of the fermentation liquid.By correlating cellular metabolism with oxygen consumption and carbon dioxide production, we found differences in the exhaust data for different metabolic pathways.

With the help of sensors, we are gradually gaining a deeper understanding of the biological fermentation process. My mentor, Professor Zhang Siliang, proposed more than 20 years ago thatThe biological fermentation process is a multi-scale complex system composed of genes, cells, and reactors.Changes in reactor operating conditions may alter metabolic pathways and affect production, and bioreactors are key to understanding how cells behave in different pathways.

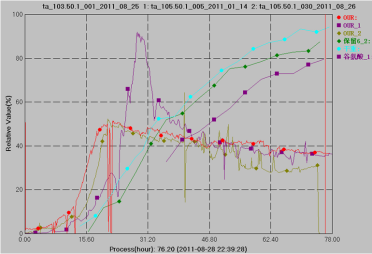

Reactor design is also crucial, as it must meet the nutrient needs of cell metabolism. During fermentation, carbon, nitrogen, and phosphorus are essential nutrients for cell expansion and require a balanced supply. Carbon not only supports cell growth, bacterial maintenance, and product synthesis, but also provides energy. Nitrogen and phosphorus are primarily required for bacterial growth. Nutrients guarantee bacterial growth, and a substrate feed strategy can ensure that all bacteria maintain high activity and efficiently synthesize metabolites. Both primary metabolism (such as amino acids and organic acids) and secondary metabolism (such as antibiotics and products of genetically engineered bacteria) are key areas of research in controlling the relationship between bacterial abundance and yield. As shown in the experimental figure below, the group with a high oxygen consumption rate actually had a low yield, demonstrating that it is more important to feed substrate on demand than to pursue high concentrations.

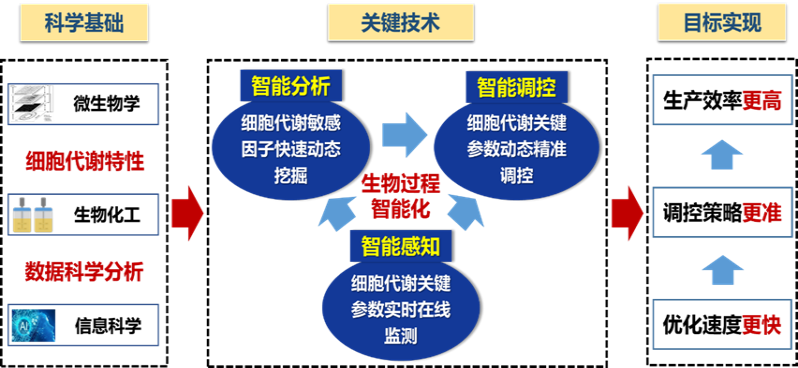

Intelligent biomanufacturing technology system: full-chain innovation of perception-analysis-regulation

Entering the intelligent era, the overall idea of intelligent biomanufacturing revolves around the complex metabolic processes of cells.The core lies in realizing an intelligent full-chain innovation system of intelligent perception, intelligent analysis and intelligent regulation.

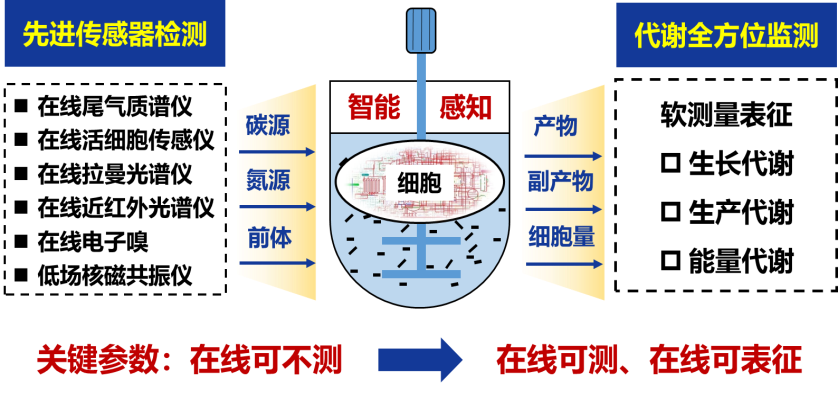

Intelligent perception is the foundation, as efficient fermentation is mostly fed-batch fermentation, requiring a comprehensive understanding of process characteristics for precise feeding.An intelligent sensing system for biomanufacturing processes has been developed, which enables all-round monitoring of metabolism through advanced sensor detection.Intelligent sensing has evolved from initially detecting basic parameters such as bacterial flora, temperature, and agitation to utilizing exhaust gas mass spectrometers (measuring exhaust oxygen, carbon dioxide, and related rates—critical parameters of aerobic fermentation). In recent years, online live cell sensors, online Raman spectrometers, and near-infrared spectrometers have been introduced. Currently, online near-infrared and mid-infrared technologies are being promoted for contactless detection, acquiring relevant data through the fermenter window. Electronic noses can detect metabolic signatures of fermentation exhaust, and low-field nuclear magnetic resonance can detect substrates and products. These technologies have made previously unmeasurable fermentation processes measurable, increasing detection efficiency from hours to seconds, far exceeding the frequency of traditional offline detection.

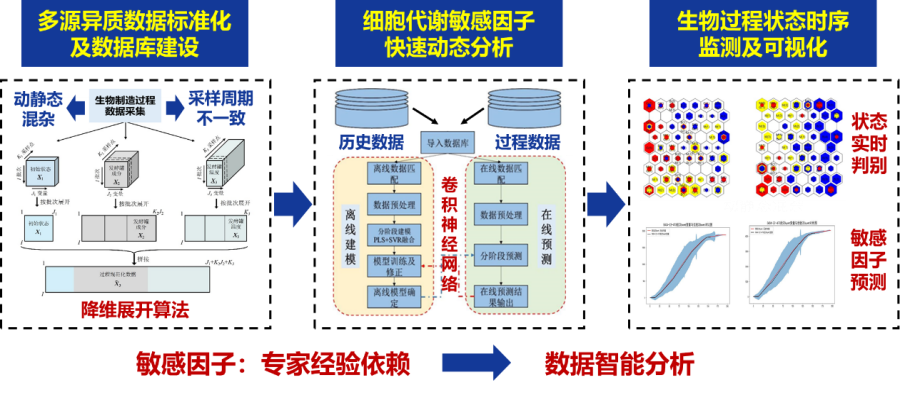

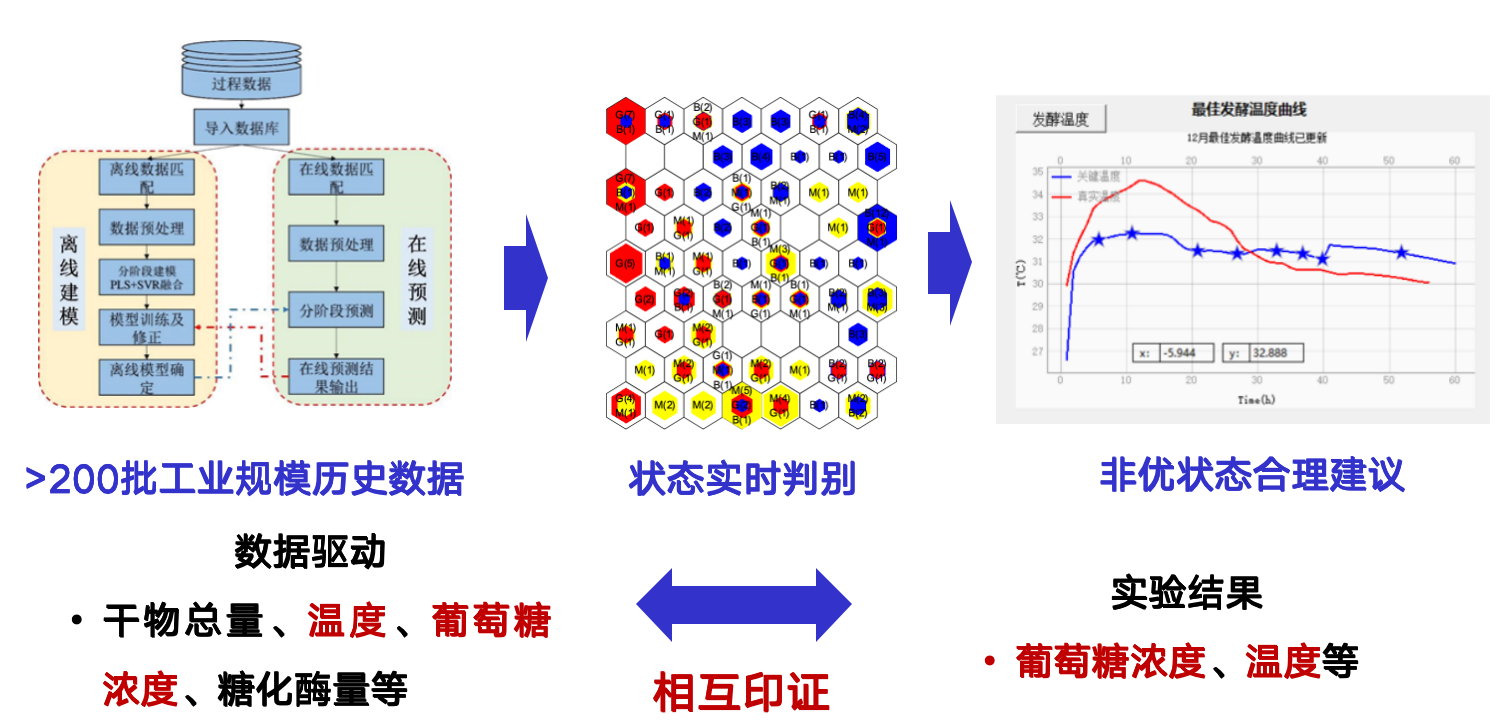

Intelligent analysis process,First, through the standardization of multi-source heterogeneous data and database construction, the cell metabolism sensitive factors are rapidly and dynamically analyzed, and finally the time-series monitoring and visualization of the biological process status are realized.Sensitive factors have evolved from initially relying on expert experience to intelligent data analysis. Therefore, data science has become crucial in connecting perception and control. Research requires identifying key control points through modeling from massive amounts of data. For example, in the case of fuel ethanol fermentation, over 100 batches of historical and process data were processed and filtered using a dimensionality reduction and expansion algorithm, retaining approximately 60-70 batches of valid data. This allows the determination of good, medium, and poor fermentation conditions and corresponding regions, guiding process optimization.

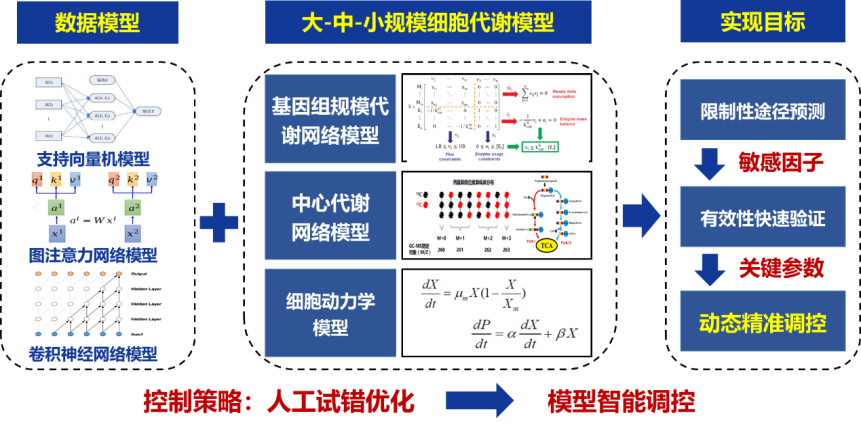

When intelligent control is used,It is necessary to combine the data model with a specific model that has the characteristics of cell metabolism, and ultimately achieve the result-oriented prediction of restrictive pathways, rapid verification of effectiveness, and dynamic and precise regulation.Control strategies have evolved from manual trial and error to model-driven intelligent regulation. To support intelligent biomanufacturing, the laboratory is equipped with fully automated intelligent bioreactors, using different models for different products. Standard sensors include oxygen, pH, Raman, and exhaust photometers. Specialized software visualizes cellular physiological and metabolic characteristics, integrates and calculates discrete parameters, and makes data more convincing, facilitating efficient regulation.

Regarding intelligent innovation of new products, I will give two research examples here.

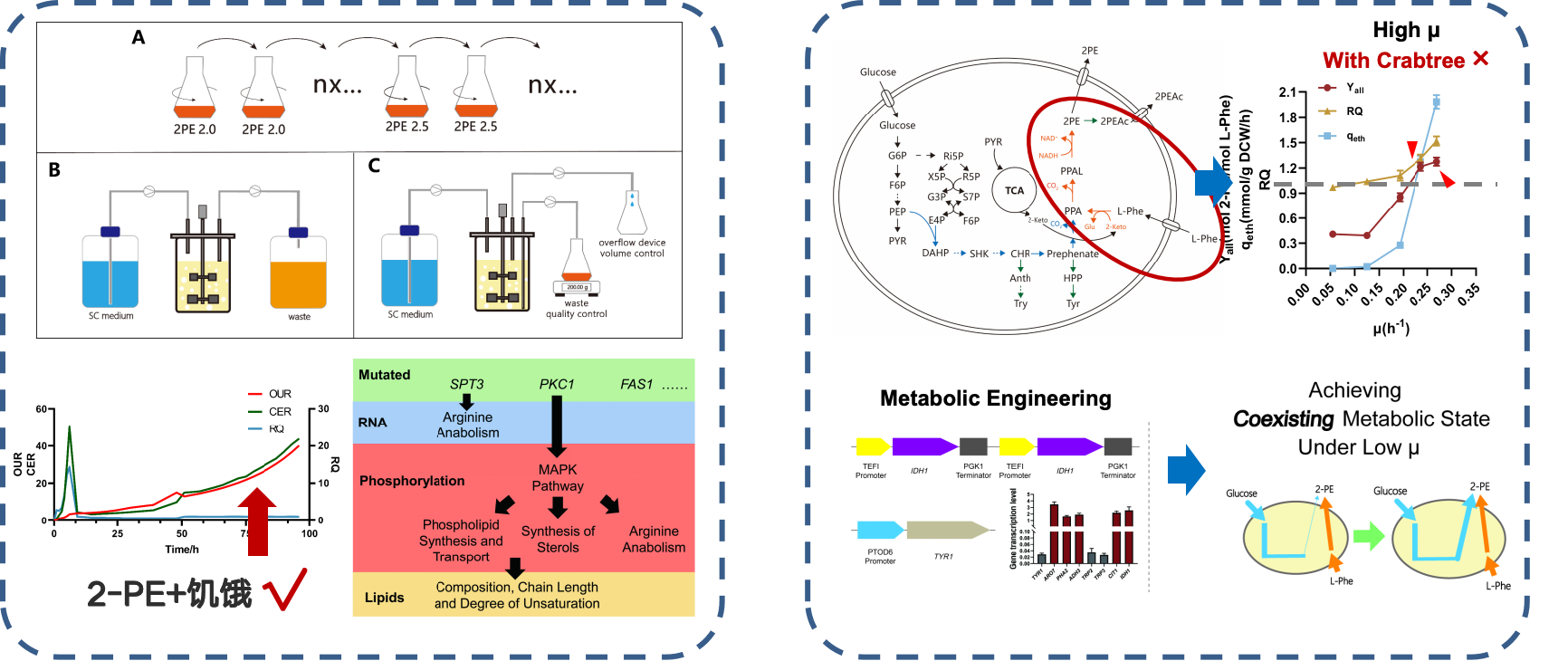

The first one is β-phenylethanol,As the second most popular flavor after vanillin, it has a wide range of applications. In terms of cost, chemically synthesized β-phenylethanol costs about $3.8 per kilogram, while natural β-phenylethanol costs as much as $1,000 per kilogram. The current price of biosynthesis is about $200 per kilogram, so chemically synthesized products still occupy a large market share. In order to promote the replacement of chemical methods with biological methods, the research team has carried out a number of tasks, including the use of adaptive evolution to screen excellent strains, combined with metabolic engineering transformation, to find the key points of process regulation. Due to the toxicity of the product, the research also directly extracted the product in the fermentation tank, which was a relatively complicated process. Ultimately, dynamic optimization was achieved based on AI, which brought the yield to 20 grams per liter. Although the manufacturing cost has been reduced compared to the previous biological method, there is still a gap with the chemical method.

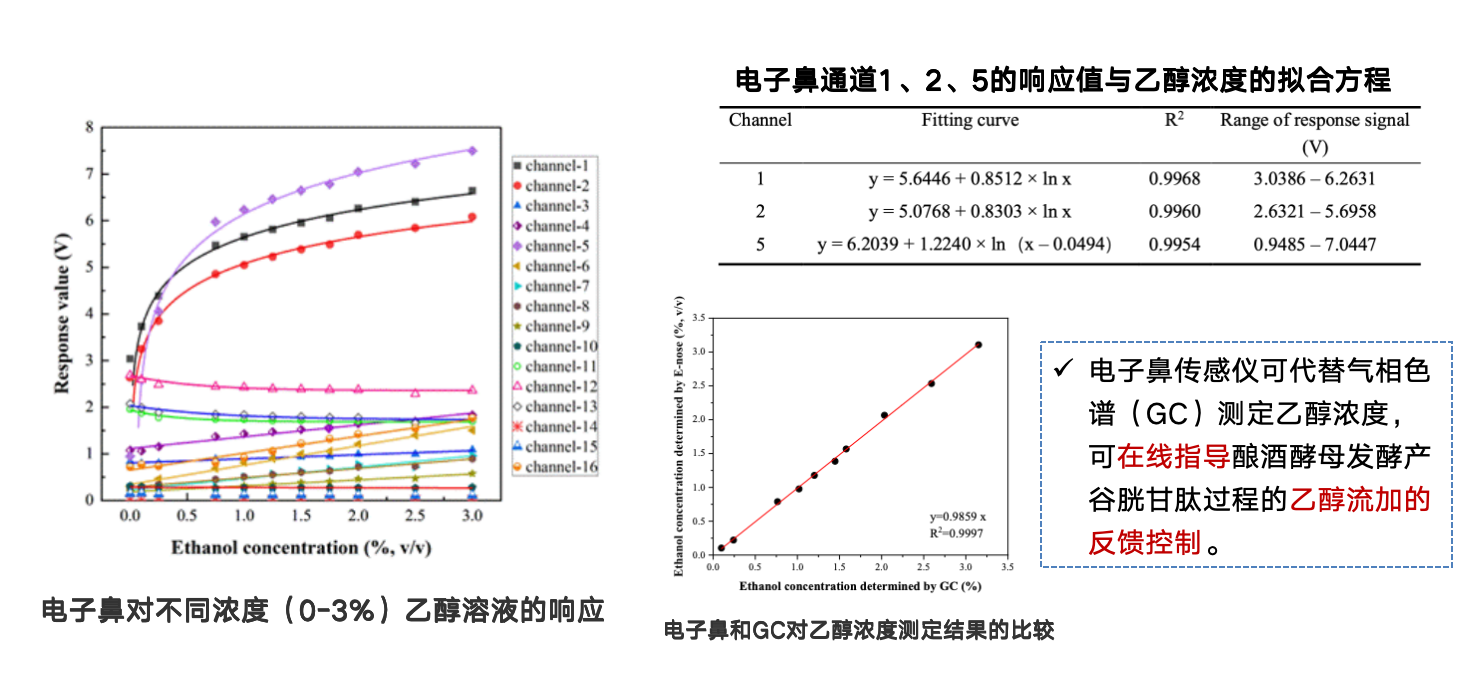

The second case is the research on glutathione.This study focused on using various sensors to enhance glutathione expression in yeast. Specifically, an electronic nose was used to detect ethanol, a metabolic byproduct of glutathione cultivation, and to explore the relationship between varying ethanol concentrations and final production. Extensive experiments revealed that when the ethanol concentration was around 1.5, glutathione concentrations could reach 4 g/L, with a peak of 66.741 TP3T, and a relatively high synthesis rate.

Case application: Intelligent optimization practice on an industrial scale

In industrial-scale biomanufacturing, we also have many typical application cases of intelligent optimization and regulation.

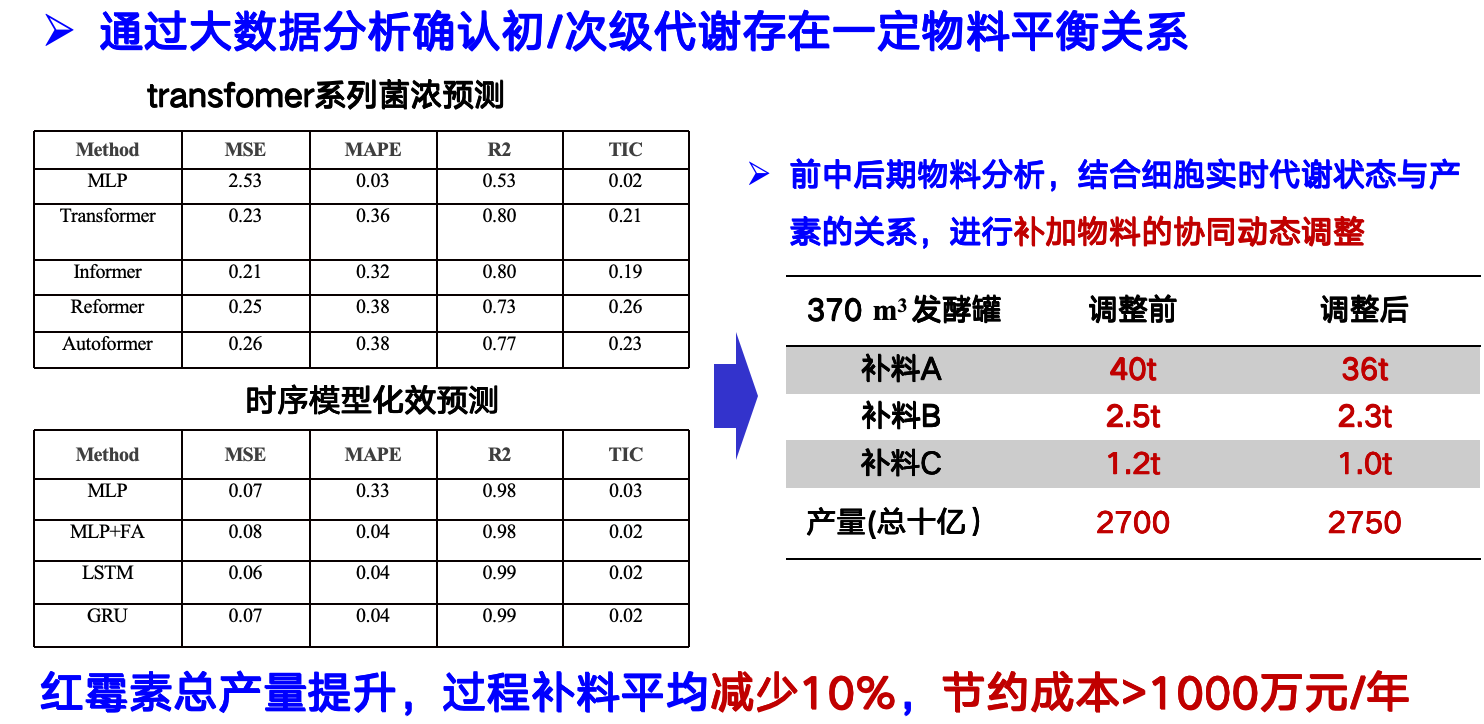

The first is the production of erythromycin. Erythromycin is a macrolide antibiotic, and its derivatives such as clarithromycin and azithromycin are widely used.During the fermentation process, we use a variety of sensors to conduct all-round, real-time, online, and multi-dimensional detection of macroscopic physiological metabolic characteristics and features with extremely high efficiency.The measurement time for sugar, alcohol, and oil concentrations has been reduced from 12 hours using traditional methods to just 2 minutes. By modeling over 100 batches of full-parameter data from a 370-ton erythromycin fermenter, we ultimately found that the erythromycin fermentation unit is most strongly correlated with bacterial concentration, viscosity, and chemical potency during the fermentation process. Based on this highly correlated model of bacterial concentration and chemical potency, sugar, nitrogen, and oil feeds for the 370-ton fermenter are now computer-determined based on this model. This allows for more precise feed amounts, resulting in increases in fermentation units and overall yield. The reduction in feed alone saves 10 million yuan annually and increases the company's annual profit by at least 60 million yuan.

The second is fuel ethanol production. In the fuel ethanol fermentation process, we also use advanced sensors and modeling, integrating advanced sensing technologies such as electronic nose, living cells, and online Raman to achieve real-time monitoring of key indicators in the industrial ethanol fermentation system.The detection time of electronic nose is 40 times shorter than that of HPLC.A data-driven approach ultimately revealed that the optimal control parameter was glucose concentration. However, by integrating this information with the factory's current operations, we discovered that temperature was a second key control factor, and controlling temperature resulted in higher ethanol yields. By increasing the circulation volume and controlling the temperature, ethanol production increased by over 3%, generating direct economic benefits of nearly 60 million yuan per year. This project helped the company become the only nationally recognized green and smart factory in the industry.

Finally, we are working on large-scale animal cell culture for rabies vaccine production. Taking BHK-21 cell culture as an example, glucose and glutamine are the two most important substrates, and previously, it was difficult to control their concentrations at low levels on an industrial scale. Using online Raman technology and online live cell detection, we have successfully controlled the concentrations of both, as well as pyruvate, at low levels.The accumulation of byproducts lactate and ammonia in cell culture decreased by approximately 20% respectively.As a result, the pH basically does not need to be adjusted during the process, the cell culture cycle is extended from 24 hours to 36 hours, the cell amount increases, and the virus titer is greatly improved, reaching 10 times that of the high-sugar control group and 1.4 times that of the manual flow-addition group. This reduces labor intensity, avoids human errors, and realizes intelligent and automated control of the entire production process.

About Professor Zhuang Yingping

The guest speaker of this sharing session is Professor Zhuang Yingping, who is currently the Dean of Qingdao Innovation Institute of East China University of Science and Technology, Director of National Biochemical Engineering Technology Research Center (Shanghai), "863" industrial biotechnology expert in biology and medicine, Vice Chairman of Biochemical Engineering Professional Committee of Chemical Industry and Engineering Society of China, and Vice President of Shanghai Society of Microbiology.

She has long been engaged in research on fermentation process optimization and scale-up. She has served as the project leader of a "973" project and the project leader of the "Reconstruction of the Shanghai Bioprocess Engineering Professional Service Platform," a base construction project of the Shanghai Science and Technology Commission. In 2021, she was approved for a key research project in the "Green Biomanufacturing" program, "Bioreactors and Intelligent Biomanufacturing." In her long-term research, she and her research team have carried out a lot of work on basic research on industrial bioprocesses, key common technology research, and technology promotion. Based on the theoretical methods for multi-scale fermentation process parameter correlation analysis, they have developed industrial bioprocess optimization and scale-up theories and methods based on the combination of cell physiological characteristics and reactor flow field characteristics, as well as related equipment. These theories and methods have been successfully applied to dozens of industrial fermentation products such as erythromycin and cephalosporin C. In recent years, she has proposed a new concept of intelligent biomanufacturing and has continuously put it into practice, continuously contributing to the technological advancement of my country's industrial biomanufacturing field. He has won three second-class National Science and Technology Progress Awards, and in recent years has won three second-class awards from Shanghai Science and Technology Progress, Light Industry Federation, Ministry of Education, etc.; as the corresponding author, he has published more than 30 articles in SCI journals such as Trends in Biotechnology and has been granted more than 30 invention patents.

Get high-quality papers and in-depth interpretation articles in the field of AI4S from 2023 to 2024 with one click⬇️