Command Palette

Search for a command to run...

After 30 Years of Perseverance, MIT Aims at the Next Generation of Lithium Batteries and Uses Generative AI to Achieve a Major Breakthrough in Solid Electrolytes

In the basement of Building 4 at MIT, there is a laboratory called "the cradle of innovation" by students - Laboratory 4-061.Professor Donald Sadoway began his research on solid polymer electrolyte (SPE) lithium metal batteries since the late 1990s.This laboratory has witnessed countless days and nights of hard work and countless experimental failures, but it is also these challenges that have given birth to innovative discoveries that have changed the world.

Over the past three decades, MIT has never slowed down its research on solid polymer electrolytes (SPE). With the rapid development of artificial intelligence technology, MIT's research team is using machine learning and data-driven strategies to launch a series of innovative research. They use advanced algorithms and massive data to break through the limitations of traditional materials and open up new possibilities for the future of battery technology.

Not long ago,Research teams from MIT and the Toyota Research Institute worked together to use generative artificial intelligence technology to completely redesign polymer electrolytes.They compared the GPT-based minGPT and the diffusion-based 1Ddiffusion and diffusion-LM models, and used pre-training and fine-tuning methods to successfully create a large number of novel, diverse and potentially valuable polymers. This achievement not only demonstrates the powerful potential of artificial intelligence in the field of material design, but also injects new vitality into the development of solid electrolytes. Reply "electrolyte" in the backend of the official account to obtain the original text of the paper.

The hope for the next generation of lithium batteries: AI-assisted breakthroughs in solid polymer electrolytes

Solid polymer electrolytes (SPEs) are widely considered to be promising candidates for next-generation lithium-ion batteries.Compared with liquid electrolytes, they show significant advantages in safety, energy density and manufacturing performance. However, the ionic conductivity of SPEs is usually several orders of magnitude lower than that of commercial liquid electrolytes, which severely limits their practical applications. To address this challenge, researchers have conducted extensive experimental and computational studies.

On the one hand, researchers have found that data mining provides a new solution for understanding the relationship between material structure and performance. As early as 2021, a research team from Shanghai Jiao Tong University published a study titled "Harnessing Artificial Intelligence to Holistic Design and Identification for Solid Electrolytes" in the journal Nano Energy. They combined machine learning models with limited DFT calculations to quickly screen out 12 candidates with extremely low electronic conductivity at room temperature from more than 29,000 designed garnet (Garnet Solid State Electrolyte) structures. This method computationally shortens the screening cycle by at least 95 years, opening up new ideas and methods for the design and discovery of solid-state electrolytes.

Paper link:

https://www.sciencedirect.com/science/article/pii/S2211285521005929

By 2023, a research team from Tohoku University in Japan built a dynamic database of all-solid-state battery electrolytes in a study titled "The dynamic database of solid-state electrolyte (DDSE)" and used machine learning to predict ionic conductivity, providing a performance reference for new materials synthesized experimentally.

Paper link:

https://www.sciencedirect.com/science/article/pii/S258996512300034X

On the other hand, researchers are also committed to improving the ionic conductivity of polymers by exploring new materials. At present, although common methods such as high-temperature operation, addition of auxiliary additives, and copolymerization have made certain progress, they mostly rely on polyethylene oxide (PEO). Limited by the limitations of the material itself, PEO materials have become a major obstacle to the development of SPE technology. However, the exploration of non-PEO polymers is still relatively limited at this stage. In order to explore a broader non-PEO polymer space, machine learning and data-driven methods have begun to be widely used in polymer property prediction and reverse design.

Although AI can accelerate the discovery of new polymers, it also brings unique challenges. In general, the accuracy of AI predictions relies on a rich, diverse, and extensive initial data set, so high-quality data is essential. In addition, designing a set of algorithms that can generate chemically realistic and synthesizable polymers is also a complex task. Therefore, among various machine learning methods, generative design stands out for its ability to learn from data and create new candidate substances. This method is not only expected to expand the polymer database by learning from existing data, but also to help customize the design of polymer materials for specific goals.

However, there are few studies that have used these advanced generative AI techniques for polymer generation. In order to study the application of generative AI techniques in non-PEO materials, especially in the field of polymer electrolytes with amorphous materials with high structural randomness,In a recent study, a research team from MIT and Toyota Research Institute delved into the complexity of different advanced generative models in polymer generation and proposed a de novo design method that can continuously generate and evaluate new GPT- and diffusion-based polymer electrolytes, providing new candidates for experimental verification.

minGPT outperforms diffusion models: pre-training strategies improve dataset adaptability

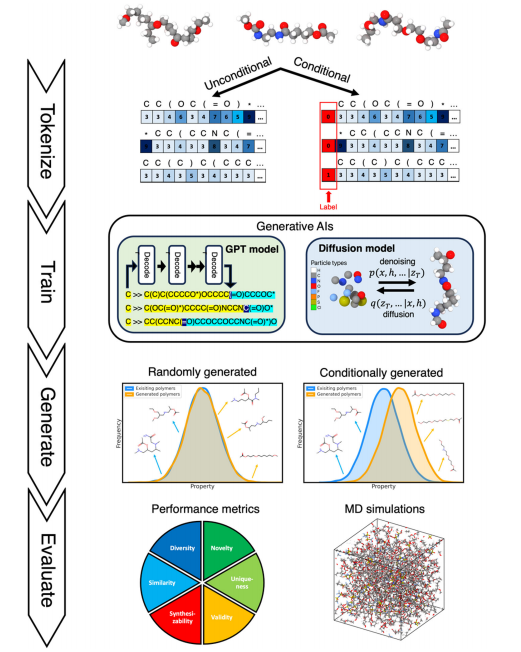

In the latest research from MIT, in order to develop valuable new polymer electrolyte materials,This study designed a systematic evaluation scheme for polymer generation through four major modules: tokenize, train, generate, and evaluate.

First, in the tokenize phase,The researchers first selected a HTP-MD dataset containing 6,024 different amorphous polymer electrolytes. The ion transport properties of these polymers were mainly calculated through molecular dynamics (MD) simulations.

Based on this data set, in the training phase,The researchers compared the performance of several different generative AI models, including minGPT, a popular open source PyTorch reproduction of the GPT model, and two diffusion models: 1D diffusion and diffusion language models.

By comparing these models, the researchers hope to find the most effective way to generate polymer electrolytes with ideal properties. Given that the three models have different loss functions, the loss value may not provide a comprehensive assessment of the chemical system. Therefore, the researchers proposed a method for evaluating polymer generation that includes 6 different indicators, which can evaluate the performance of the model under different hyperparameter combinations.

* The 1Ddiffusion model is an improvement on the Denoising Diffusion Probabilistic Model (DDPM), which was originally developed for image generation.

* In the diffusion-LM model, the non-autoregressive language model architecture is combined with the concept of continuous diffusion for text generation.

* minGPT project address:

https://gitcode.com/gh_mirrors/mi/minGPT

* 1Ddiffusion project address:

https://gitcode.com/gh_mirrors/de/denoising-diffusion-pytorch

* diffusion-LM project address:

https://gitcode.com/gh_mirrors/di/Diffusion-LM

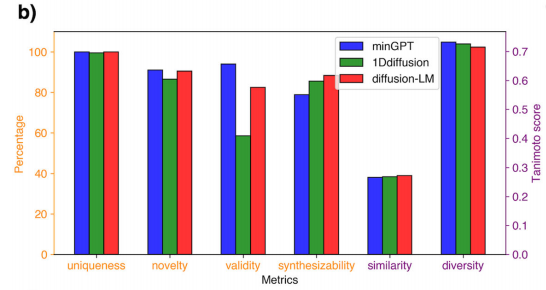

In this study, the researchers first studied the performance of the model architecture in the unconditional generation case, that is, using the HTP-MD dataset to train the generative model to learn the "language" of polymers without any attribute constraints.The model can be trained in the Generate phase to randomly generate novel, chemically valid, unique, and synthesizable polymers.

The results are shown in the figure below. The minGPT model and the diffusion-LM model perform similarly, while the 1Ddiffusion model performs relatively poorly. In terms of computational cost, the minGPT model is more efficient than the diffusion-based model in both training and inference. On a Tesla V100 GPU core (16GB RAM), training the optimal minGPT model only takes about 3-4 minutes, while the optimal 1Ddiffusion and diffusion-LM models take about 2 hours to train.

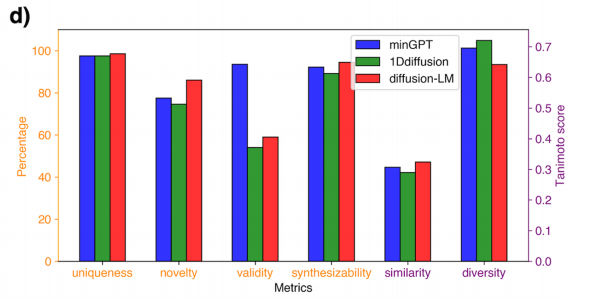

Next, the study further guided the generative model to create polymer electrolytes with ideal properties and studied the performance of the model architecture under conditional generation. For example, in order to achieve high ionic conductivity, the researchers first divided the polymers in the HTP-MD dataset into two groups: high conductivity and low conductivity. Then, they used the optimal model architecture obtained from the hyperparameter adjustment of the unconditional generation task to conditionally generate polymer electrolytes with high conductivity in the generation stage.

Finally, they used a graph neural network (GNN) model to predict the ionic conductivity of the resulting polymers.Among the 46 candidate materials tested, 17 polymers with superior ionic conductivity were finally screened out.The results also show that consistent with the findings on unconditional generation, the minGPT model also outperforms the 1Ddiffusion and diffusion-LM models in conditional generation, achieving a superior average score.This demonstrates that the minGPT model not only performs well in generating novel polymers but can also effectively guide the generation of polymer electrolytes with specific ideal properties.

Since the minGPT model outperforms the diffusion-based model in both unconditional and conditional generation. Therefore, the researchers further studied the impact of pre-training and fine-tuning methods on the minGPT model. Specifically, they compared two different training strategies: one is a minGPT model trained directly on the HTP-MD dataset from scratch, and the other is a minGPT model that is first pre-trained on the PI1M database for unconditional generation and then fine-tuned on the HTP-MD dataset for conditional generation.

* PI1M database: a benchmark database containing 1 million polymer monomers, but lacks information on the ionic conductivity of polymers

The results show that the pre-training strategy significantly shortens the training time of fine-tuning and improves the effectiveness and uniqueness scores of conditional generation. In addition, pre-training enhances the model's ability to capture the characteristics of polymers in the HTP-MD dataset and produces a wider diversity of polymers during generation. This means thatBy pre-training on a large-scale database, the model can better adapt to the needs of a specific dataset, thereby showing higher efficiency and accuracy in generating new polymers.

MIT and Toyota Research Institute work together to promote the widespread use of AI in the automotive field

In fact, this research is not the first collaboration between MIT and the Toyota Research Institute. The history of cooperation between the two sides can be traced back 10 years ago, and the results are quite fruitful.

As early as September 2015, Toyota Motor Corporation announced that it would invest 50 million US dollars in the next five years to establish a research center in cooperation with MIT and Stanford University to jointly develop driverless cars. This cooperation laid the foundation for the widespread application of AI in automobile research and development.

Just one year later, MIT's Transportation and Logistics Center AgeLab and Toyota's Collaborative Safety Research Center (CSRC) jointly released an innovative open dataset called DriveSeg. This dataset captures driving scenes through videos, providing a data stream that is closer to real dynamic driving situations, greatly promoting the development of machine learning, scene understanding, and behavior prediction.

In 2020, a research team from MIT, Toyota Research Institute, and Stanford University published a paper in Nature titled "Closed-loop optimization of fast-s protocols for batteries with charging machine learning," introducing a machine learning model.The model reduces battery charging test time by nearly 15 times from nearly two years to 16 days.The method can also accurately predict the battery's service life. This method is expected to accelerate various aspects of battery development and help manufacturers design and manufacture batteries more efficiently.

Paper link:

10.1038/s41586-020-1994-5

Although the five-year agreement has expired, the cooperation between the parties has not stopped. In 2021, the research team from MIT, Toyota Research Institute, Stanford University and SLAC once again published an article in Nature Materials titled Fictitious phase separation in Li layered oxides driven by electro-autocatalysis.For the first time, "scientific machine learning" was applied to battery cycle research.It overturns traditional assumptions about charging and discharging lithium-ion batteries and provides new rules for designing long-life electric vehicle batteries that can be fully charged in 10 minutes.

Paper link:

10.1038/s41563-021-00936-1

Now, MIT and the Toyota Research Institute have teamed up again to develop a method for continuously generating and evaluating new polymer candidates, an approach that has great potential for solving complex polymer design problems and advancing the search for next-generation battery materials.

Upgrading and transformation of the lithium battery industry: AI helps drive key developments

From the widespread use of electric vehicles to consumer electronics such as smartphones and laptops that we use daily to smart home devices, lithium batteries provide powerful power support for these devices with their efficient energy storage capabilities.

Globally, governments have paid great attention to the development of lithium batteries. For example, in order to implement the "Implementation Plan for the New Industry Standardization Pilot Project (2023-2035)", the Ministry of Industry and Information Technology and other four departments just issued the "National Lithium Battery Industry Standard System Construction Guidelines (2024 Edition)" in November 2024, aiming to strengthen the top-level design of lithium battery industry standards and promote the healthy and orderly development of the lithium battery industry.

Countries and regions such as the United States, Europe, and South Korea are also increasing their investment in lithium battery research and development to ensure that they remain ahead in global competition. For example, in November 2021, the Federal Advanced Battery Alliance (FCAB), jointly established by the U.S. Department of Energy, the Department of Defense, the Department of Commerce, and the State Department, released the 2021-2030 U.S. Lithium Battery National Blueprint, which aims to guide investment in the U.S. lithium battery manufacturing value chain and create jobs. These policies not only promote technological innovation, but also provide a solid foundation for the widespread application of lithium batteries.

However, due to the continuous improvement of performance requirements for different devices, the current research and development of lithium batteries still faces continuous challenges and innovation needs, such as relatively slow progress in material innovation and the difficulty in effectively processing and analyzing large amounts of battery data.

The lithium battery industry is at the crest of a wave of technological innovation, and AI is undoubtedly the core driving force leading this technological renaissance.For example, as the world's largest lithium battery manufacturer, CATL has used AI technology to optimize the recycling process and has made significant progress in the field of lithium battery recycling, increasing the lithium recovery rate to 91%. Innosilicon uses advanced artificial intelligence algorithms and big data analysis technologies to deeply optimize all aspects of lithium battery production, which not only improves the level of intelligent lithium battery production, but also accelerates the research and development and application of new lithium battery materials.

In the future, the lithium battery industry will continue to undergo significant upgrades and changes. With the continuous advancement of technology and the continued growth of market demand, lithium batteries will play an increasingly important role in energy transformation and sustainable development. During this journey, AI technology is showing an unprecedented attitude, providing a continuous key driving force for the further upgrading of the industry.